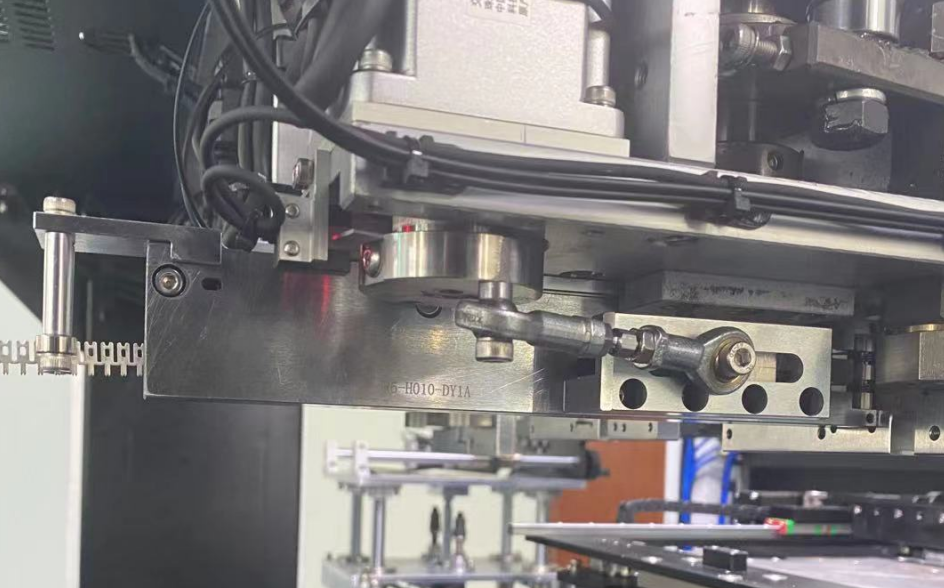

Cia saib nws ua haujlwm li cas:

Wkaus mom yogNias-haum?

Xovxwm-fit yog ib qho kev cuam tshuam haum ntawm ob qhov chaw uas ib feem raug yuam kom nyob rau hauv lub siab rau hauv ib lub qhov me me ntawm lwm qhov.

Qhov tseeb, nws yog ib hom kev cuam tshuam haum.

Xovxwm haum thev naus laus zis tau siv dav, thiab kev sib txuas ntawm PCB yog ib qho ntawm nws cov ntawv siv.

Thaum piav qhia ua lus Suav, peb feem ntau siv cov ntsiab lus sib txawv xws li crimping, nias haum, thiab crimping.Kev lag luam feem ntau siv ncaj qha siv "Nias haum" los piav qhia.Lub ntsiab lus tseem ceeb ntawm tsab xov xwm no kuj tseem yog daim ntawv thov haum rau hauv PCB kev lag luam (ntau hom xovxwm haum pins).

Dab tsi yog qhov zoo ntawm Press haum?

Cov txheej txheem tseem ceeb rau kev txhim kho qhov chaw ntawm PCB yog vuam thiab nias haum.Cia peb sib piv qhov zoo thiab qhov tsis zoo ntawm ob txoj kev sib txuas no nrog qee cov ntaub ntawv sib xyaw.

| Soldering | Nias-haum | |

| noj | 30-40 kW | 4-6 kW |

| ib puag ncig | Vuam cua thiab chaw nyob | Tsis muaj chaw nyob |

| nqi | Xav tau PA, PPS | Tsis muaj teeb meem ntawm qhov kub thiab txias, siv cov khoom siv qis dua xws li PBT, PET thiab lwm yam. |

| Khoom siv | Loj peev thiab loj cheeb tsam tus nqi | Tsawg nqis peev thiab thaj chaw me me |

| Muaj qhov chaw | 5-15 hli | 2 hli |

| Tus nqi tsis raug | 0.05f ua | 0.005 ua |

Los ntawm cov ntaub ntawv sib piv, peb tuaj yeem pom tias Xovxwm haum yog ib txoj kev sib txuas ntawm PCB zoo dua li vuam ntawm qee qhov ntsuas kev ua tau zoo.Tau kawg, vuam tsis muaj txiaj ntsig, txwv tsis pub yuav tsis muaj ntau cov ntsiab lus vuam ntawm PCB.Piv txwv li, welding feem ntau muaj kev kam rau siab dua rau qhov ntev ntev ntawm cov pins, thiab qhov kev sib txuas ntawm vuam yog ruaj khov dua, Txawm li cas los xij, Xovxwm Fit yog qhov zoo dua nyob rau hauv ntau qhov taw qhia.

Common Press haum cov qauv tsim

Ua ntej qhia txog tus qauv tsim, nws yog ib qho tsim nyog yuav tsum ua kom paub ob nqe lus uas siv ntau:

PTH: Plated los ntawm qhov

EON: Qhov muag ntawm koob

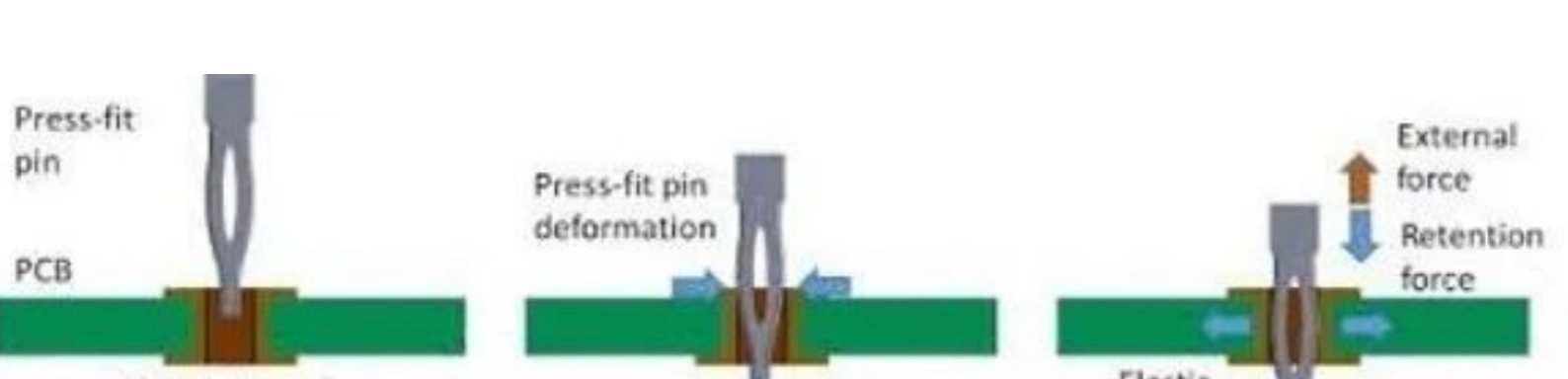

Tam sim no, cov pins siv ntawm Xovxwm haum yog qhov yooj yim pins elastic, tseem hu ua tus pins raws, uas feem ntau loj dua li PTH.Thaum lub sij hawm sib dhos txheej txheem, cov koob yuav raug deformed, uas ua rau qhov kev sib txuas nto nrog PTH nruj.Piv nrog rau cov khoom siv koob, cov koob ua raws cai tuaj yeem tso cai rau PTH siab ntev dua.

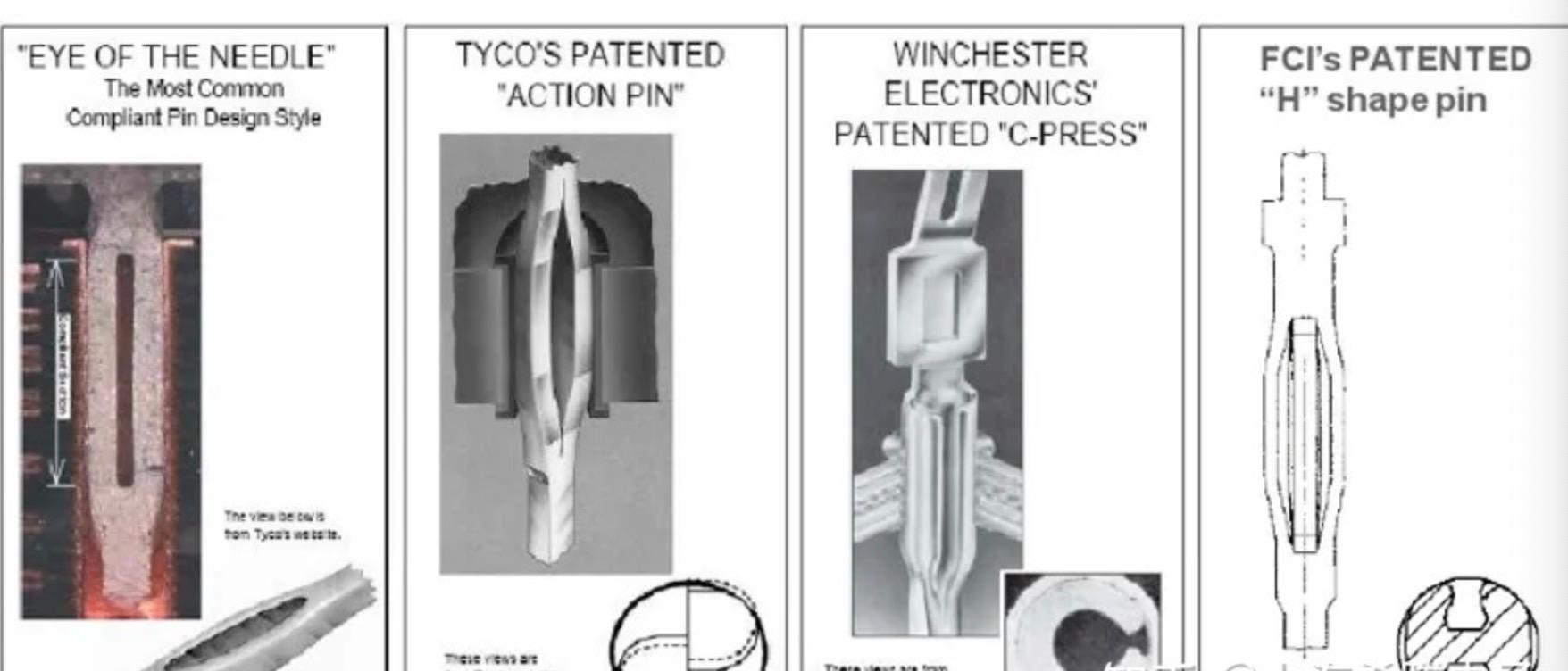

Tus pin qhov koob tau maj mam dhau los ua lub ntsiab hauv kev ua lag luam.Nws yog qhov yooj yim hauv kev tsim thiab tuaj yeem siv nrog qhib patents.Txawm hais tias nws tsis xav tau kev tsim qauv ntau dhau, nws kuj tseem tuaj yeem siv nrog kev npaj tsim cov kev daws teeb meem, uas muaj cov yam ntxwv ntawm lub zog qis qis thiab siab tuav lub zog.

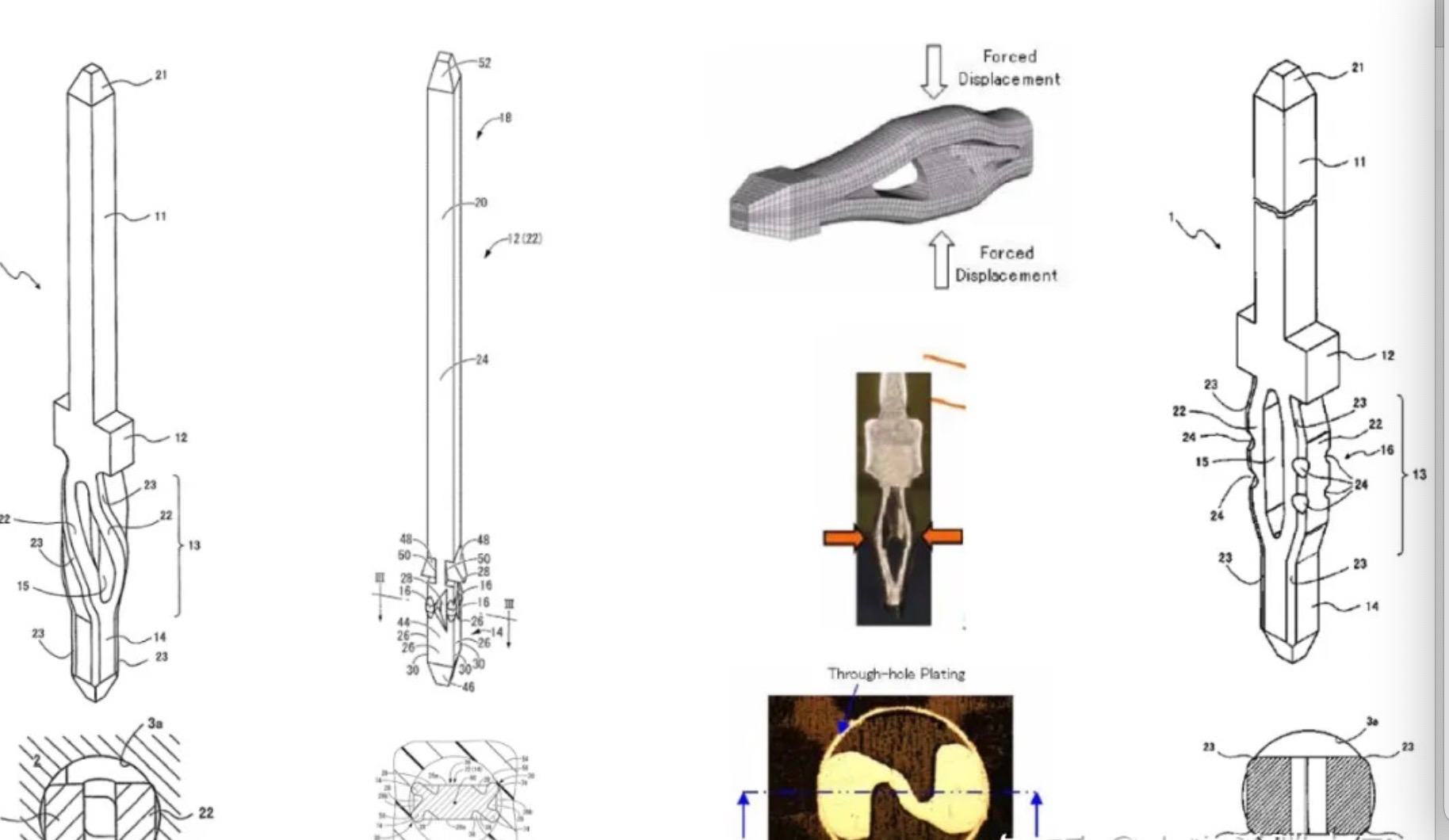

Daim duab saum toj no qhia tau hais tias ntau tus pin / davhlau ya nyob twg cov qauv.Thawj yog cov qauv tsim ntau tshaj plaws.Cov txheej txheem tsim pinhole yooj yim yog qhov yooj yim hauv cov qauv, tab sis yuav tsum muaj qhov sib luag thiab qhov chaw;Qhov thib ob yog cov khoom patent ntawm TE Company.Raws li tus qauv pinhole, nws muaj lub kaum sab xis ntau dua, uas tuaj yeem hloov mus rau qhov sib txawv.Txawm li cas los xij, nws muaj qhov xav tau ntau dua rau lub qhov taub, thiab nws yuav tsim ib qho kev sib hloov quab yuam ntawm lub qhov;Qhov thib peb yog Winchester Electronics ' yav dhau los patent "C-PRESS", uas yog tus cwj pwm los ntawm C-puab los ntawm tus ntoo khaub lig.Qhov zoo yog tias lub zog nias yog tas mus li, PTH deformation me me, thiab qhov tsis zoo yog tias PTH nrog me me aperture yog qhov nyuaj rau ua tiav;Qhov kawg yog H-hom tus pin ntawm FCI Company.Qhov zoo dua yog tias nws yooj yim los tswj thaum crimping, tab sis qhov tsis zoo yog tias nws nyuaj rau kev tsim tus pin hu.

Cov khoom siv thiab cov txheej txheem tsim khoom

Cov khoom siv ntawm Pin muaj xws li tin bronze (CuSn4, CuSn6), tooj dag (CuZn), thiab tooj liab dawb (CuNiSi), cov tooj liab dawb muaj cov conductivity siab, thiab kev siv kub tuaj yeem tshaj 150 ℃;Cov txheej txheej feem ntau yog plated los ntawm electroplating lossis kub dip plating μ m + 1 μ M ntawm Ni + Sn, SnAg lossis SnPb, thiab lwm yam. Raws li tau piav qhia saum toj no, tus qauv ntawm Pin yog ntau haiv neeg, thiab lub hom phiaj kawg yog los tsim tus Pin nrog me me. nias quab yuam thiab loj tuav quab yuam nyob rau hauv cov xwm txheej ntawm kev tsim khoom yooj yim thiab tus nqi qis.

Cov khoom siv feem ntau ntawm PTH yog iav fiber ntau + epoxy resin + tooj liab ntawv ci, nrog thickness> 1.6, thiab txheej feem ntau yog tin lossis OSP.Cov qauv ntawm PTH yog qhov yooj yim.Feem ntau hais lus, tus naj npawb ntawm PCB txheej yog ntau dua 4. Lub aperture ntawm PTH feem ntau nruj, thiab cov kev cai tshwj xeeb yog nyob ntawm tus tsim ntawm Pin.Feem ntau, lub thickness ntawm tooj liab plating yog li 30-55 μ m.Lub thickness ntawm tin deposition feem ntau> 1 μ m.

Analysis ntawm xovxwm haum / rub tawm txheej txheem

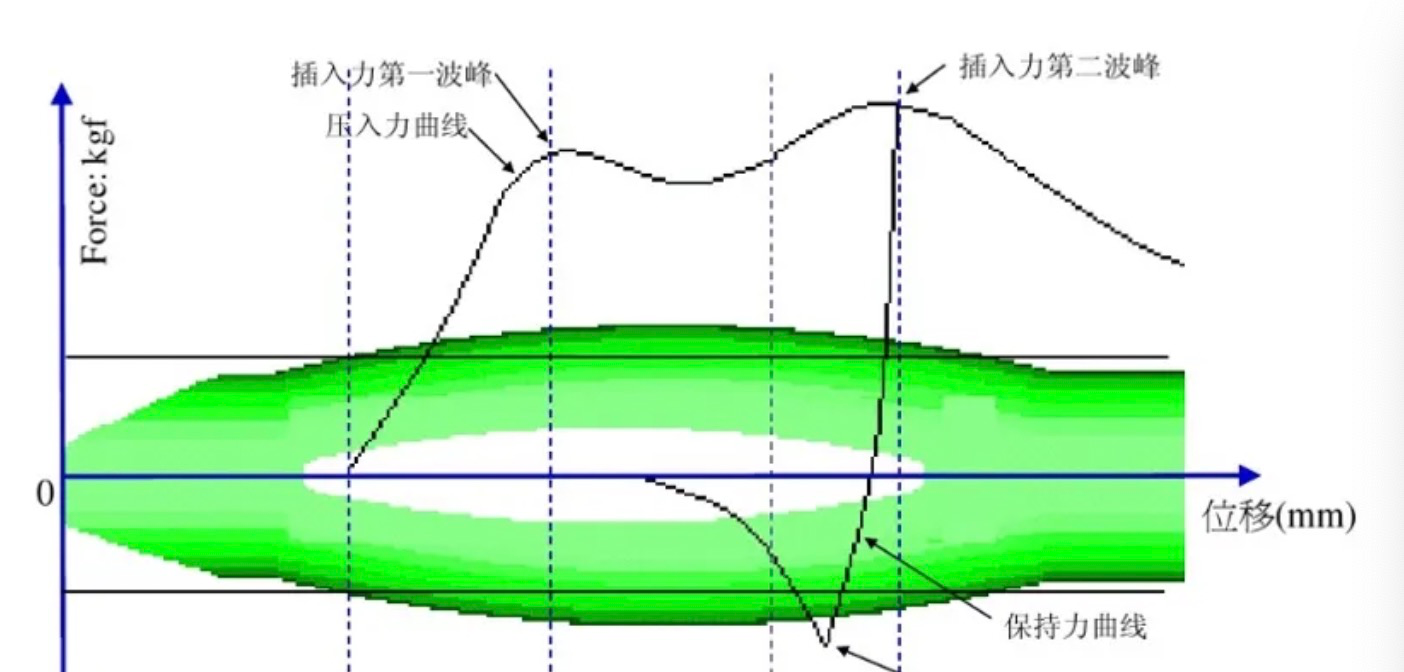

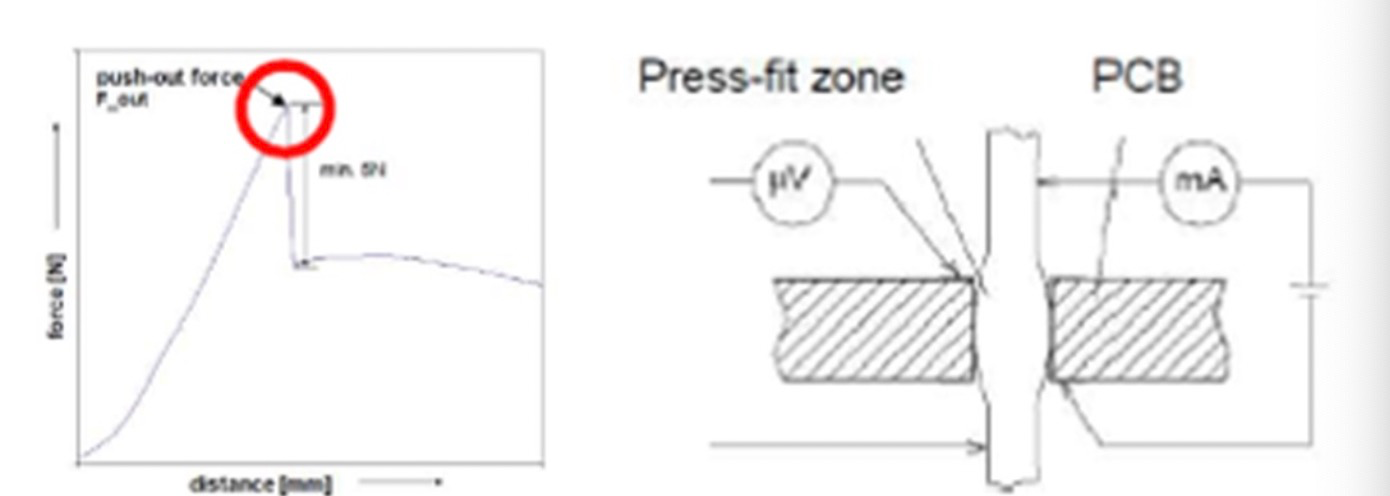

Noj cov qauv pinhole feem ntau ua piv txwv, raws li qhia hauv daim duab hauv qab no, muaj qhov hloov pauv ntawm lub siab nkhaus nyob rau hauv tag nrho cov txheej txheem ntawm nias rau hauv thiab rub tawm, uas tseem cuam tshuam rau tus qauv tsim ntawm Pin.

Nias hauv txheej txheem:

1. Pin yog muab tso rau hauv lub qhov, thiab lub taub hau nkag mus yam tsis muaj deformation

2. Pin pib nias rau hauv, EON pib deform, thiab thawj nthwv dej ncov tshwm nyob rau hauv cov txheej txheem nias

3. Pin txuas ntxiv mus, EON yeej tsis muaj deformation ntxiv, thiab lub zog nias qis me ntsis

4. Pin txuas ntxiv mus, ua rau deformation ntxiv, thiab lub nthwv dej thib ob

tshwm nyob rau hauv cov txheej txheem nias

Tsis pub dhau 100 vib nas this tom qab xovxwm haum tiav, lub zog tuav yuav poob sai, nrog rau qhov poob ntawm li 20%.Yuav muaj qhov sib txawv raws li tus pin sib txawv;24 teev tom qab xovxwm haum, cov txheej txheem vuam txias ntawm Pin thiab PTH yog qhov pib ua tiav.

Qhov no yog tshwm sim los ntawm lub cev muaj zog ntawm cov hlau, thiab tsis muaj chaw me me rau kev txhim kho.Nws tuaj yeem txheeb xyuas seb qhov kev tuav pov hwm zaum kawg ua tau raws li cov khoom tsim los ntawm kev thawb tawm quab yuam.

2. Qee hom tsis ua hauj lwm thaum lub sij hawm Pin insertion

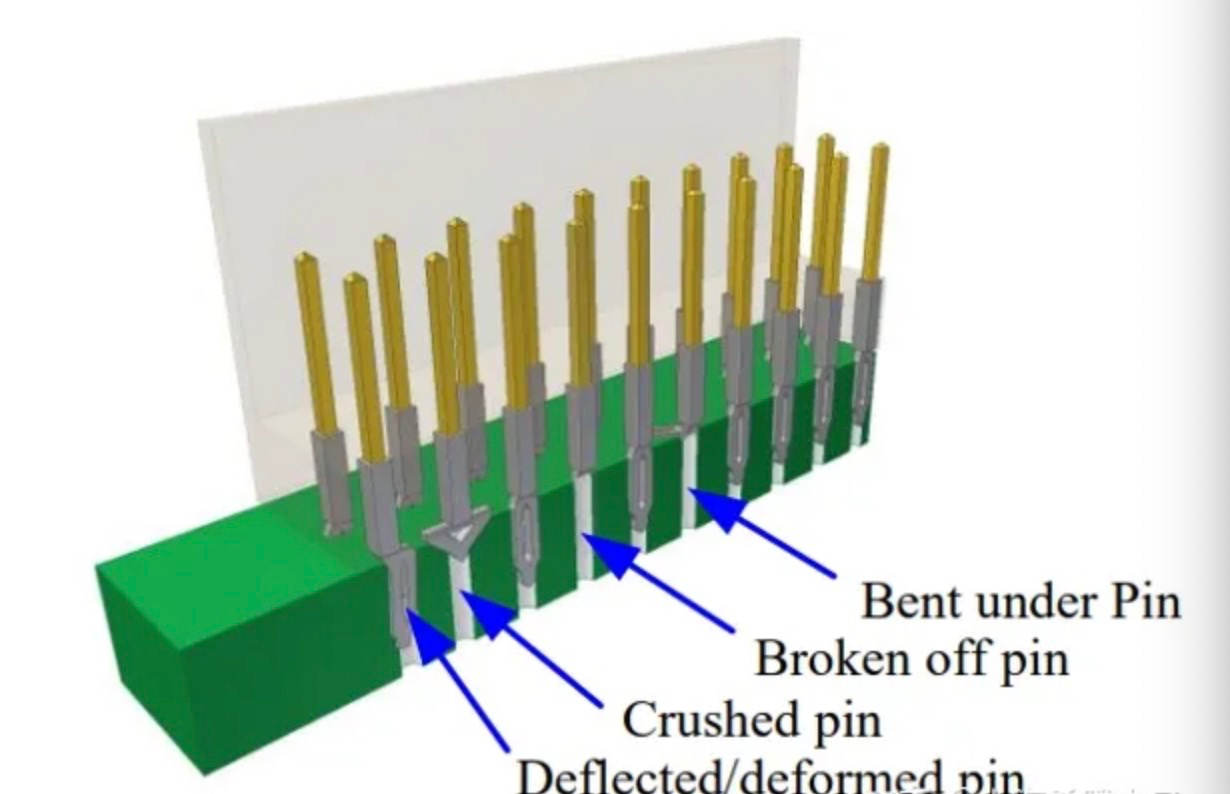

Raws li pom nyob rau hauv daim duab hauv qab no, tus pin yuav deformed, crushed, crushed, tawg thiab khoov thaum lub sij hawm insertion.

Cov no yog cov kev ua tsis tau zoo ntawm tus pin hu thaum lub sijhawm xovxwm haum.Txij li thaum tus pin tiv tauj yuav tsum tau muab tso rau hauv PTH, nws muaj feem ntau tias nws tsis tuaj yeem pom qhov muag pom tom qab nias, thiab kev puas tsuaj ntawm lub zog ntawm lub zog yuav tsis raug kuaj pom los ntawm kev ntsuas hluav taws xob.

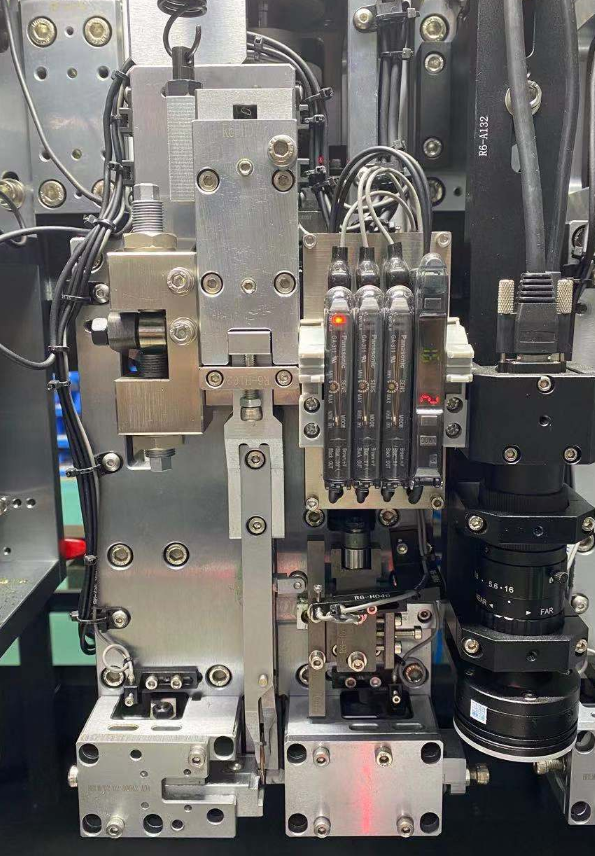

Cov hom tsis ua haujlwm no yuav tsum tau saib xyuas thaum lub sijhawm xovxwm haum.PROMESS muab txoj kev nkhaus nkhaus, qhov rais, qhov siab tshaj plaws thiab qhov tsawg kawg nkaus thiab lwm txoj hauv kev saib xyuas kom ntseeg tau tias tag nrho cov xovxwm haum txheej txheem ntawm txhua tus pin yog tswj tau thiab txhim khu kev qha.Koj tuaj yeem pom cov ntaub ntawv tso rau hauv video dua.PROMESS muab kev ua haujlwm siab, 100% cov txheej txheem tswj kev daws teeb meem kom ntseeg tau tias txhua yam khoom tawm hauv lub Hoobkas tsis muaj cov khoom tsis raug, Cov txheej txheem tswj kuj tseem tuaj yeem txo cov khoom pov tseg ntawm PCB board rau qee qhov thiab txo cov nqi tsim khoom.

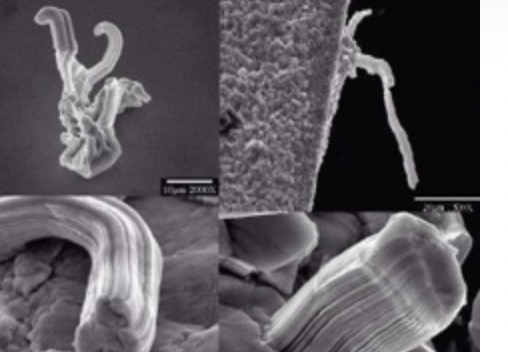

3. luv Circuit Court

Nyob rau saum npoo ntawm cov tin ntshiab, qhov kev ntxhov siab yuav txhawb kev loj hlob ntawm tin Whisker, uas yuav ua rau luv luv Circuit Court ntawm lub rooj tsavxwm luam tawm, yog li ua rau muaj kev phom sij rau kev ua haujlwm ntawm lub module.Cov txheej txheem tsim los txo qhov kev loj hlob ntawm tin whiskers suav nrog txo qhov kev quab yuam thiab txo cov thickness ntawm cov tin nto.

Cov ntaub ntawv PTH feem ntau muaj xws li tooj liab, nyiaj, tin, thiab lwm yam

Yuav daws qhov teeb meem ntawm tin whiskers li cas?

Thaum lub sij hawm nias, lub zog nias yuav tsum tsis txhob loj heev, uas yog tswj cov txheej txheem nias.Tom qab nias, kev tshuaj ntsuam xyuas tuaj yeem ua tiav, thiab cov tin whiskers yuav tsum tau soj ntsuam rau 12 lub lis piam

4. Qhib Circuit Court

Dav hlau nyhuv / rub down:

Thaum lub sij hawm tus txheej txheem ntawm nias nyob rau hauv Pin, cov ntawv luam Circuit Court board tej zaum yuav mechanically puas.Yog tias qhov kev sib txhuam loj dhau lawm, qhov saum npoo ntawm lub rooj tsav xwm yuav raug khawb, kev sib txhuam yuav nce, thiab thaum kawg PTH yuav raug thawb tawm los ntawm theem.Txo lub siab kuj tuaj yeem zam lub dav hlau nyhuv.

Whitening nyhuv / delaminate:

Thaum lub sij hawm nias mounting, txhua txheej txheej ntawm cov ntawv luam tawm Circuit Board yuav raug nyem.Yog hais tias qhov kev siv quab yuam loj dhau los yog PTH tsis ruaj khov, lub rooj tsav xwm luam tawm yuav raug delaminated.Tom qab ib lub sijhawm, cov dej noo yuav nkag mus rau hauv cov kab nrib pleb ntawm cov ntawv luam tawm Circuit Board, uas ua rau txo qis kev sib cais.

Ob qhov teeb meem no tuaj yeem tswj tau qee qhov thaum lub sij hawm xovxwm haum los ntawm kev tswj lub zog nias.Tom qab cov xovxwm haum tiav lawm, cov khoom tuaj yeem raug tshuaj xyuas los ntawm kev tiv thaiv kev tiv thaiv kev ntsuas thiab ntsuas metallographic.Kev ntsuas kev tiv thaiv kev tiv thaiv tuaj yeem siv los ua cov khoom siv niaj hnub, thiab kev tshuaj xyuas metallographic nws tus kheej yog kev puas tsuaj rau cov khoom, yog li kev soj ntsuam tsis tu ncua tuaj yeem nqa tawm.

Cov txheej txheem kev soj ntsuam kev ntseeg tau ntawm cov khoom

Ib qho ntawm cov kev tshawb pom ntau tshaj plaws yog kev kuaj kev laus thiab lwm qhov yog kev sib txuas cov yam ntxwv kuaj

Kev laus yog simulate lub xeev tom qab siv sij hawm ntev los ntawm cov khoom siv kuaj.Cov txheej txheem aging muaj xws li:

1. Cov dej yaug sov: - 40 ℃ ~ 60 ℃, hloov tsis tu ncua rau 30 feeb

2. Kub kub: 125 ℃, 250 teev

3. Kev nyab xeeb ib ntus: 16 teev kub kub → 24 teev kub thiab av noo → 2 teev kub →

4. Kev vibration

5. Gas corrosion: 10 hnub, H2S, SO2

Qhov kev sim no tsuas yog los ntsuas lub zog thawb thiab kev ua haujlwm hluav taws xob.

Cov txheej txheem muaj xws li:

1. Push tawm quab yuam (tuav lub zog): > 20N (raws li cov khoom tsim nyog)

2. Tiv tauj tiv thaiv: < 0.5 Ω (raws li cov khoom tsim nyog)

Post lub sij hawm: Nov-10-2022

Youtube

Youtube